What is RFID?

You might not know what an RFID inventory tracking device is, but chances are you’ve experienced an RFID in action. RFID stands for radio-frequency identification, and refers to wireless devices that use electromagnetic fields to allow RFID readers to identify objects and capture data about those objects. In short? You’ve likely encountered RFID readers in a vast number of settings. For example;

- at your local department store as someone swipes shelves marked with an inventory tag

- at work when you swipe your ID pass to open a door

- paying for something without cash using a quick tap to pay

- if you’ve ever had your veterinarian microchip your cat or dog in case they get lost

- RFID is used to track objects like automobiles, pharmaceuticals, and livestock through the assembly process and into the sales chain

Unlike bar code technology, RFID readers can read an RFID tag in the vicinity, and don’t require a direct line of sight. RFID technology can also identify individual items in a supply chain. To a bar code reader, every box of Tylenol is exactly the same because they all have the same bar code used at the checkout. RFID can provide additional information to track a specific box of Tylenol including its Lot and Manufacture date/time for example.

How does it work?

An RFID inventory tracking system consists of two parts; the microchip/antenna that is attached to the object that will be tracked, typically referred to as a tag; and an RFID reader that uses electromagnetic waves to read the tag and collect the data. The radio waves emitted are low (comparable to a car radio) and aren’t considered harmful.

Sounds expensive. What’s in it for me?

While it’s true that many companies look into investing in RFID technology and decide not to, due to its cost, it’s often because they aren’t sure how the technology can benefit them and result in significant savings. In its most basic application, RFID readers can reduce man-hours spent on taking inventory by 90%. This frees up employees for higher-value tasks. The US Navy reported a 98% reduction in time spent taking inventory of supplies when they implemented RFID inventory tracking. Large-scale farming operations use RFID to manage harvests efficiently and reduce waste. Agri-food clients use RFID tags to let them know if the temperature of food in shipment has been compromised. This ensures food safety and protect their reputations.

The key to figuring out whether RFID inventory tracking might be right for your business is assessment and planning: be honest about where your company needs to improve, and have an idea of how improvements would impact your bottom line. For example, if a farming operation reduced waste by 13% by implementing RFID to ensure produce arrived to market within a specified timeframe, how would that translate into dollars saved? If you only plan to use RFID to replace your existing bar code system, it’s probably too much fire-power for your needs. Businesses that manage the movement of a lot of goods, particularly high-value goods, are the biggest adopters of RFID technology, but even smaller companies can benefit from implementing smaller-scale RFID inventory tracking solutions to improve specific areas of their supply chains.

PiiComm’s specialists can help you to determine what your business case could look like for implementing RFID technology. Feel free to contact us anytime and we would be happy assist.

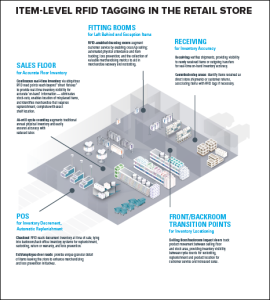

Learn more about item-level RFID tagging in retail: click here